The College of Education for Pure Sciences at the University of Basra discussed the preparation and diagnosis of some superimposed polymers

Derived from heterocyclic rings

With nanometal oxides and their applications

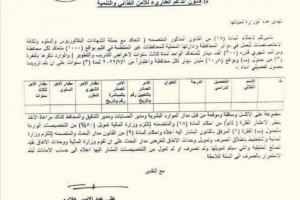

The thesis presented by the researcher (Hassan Jaber Hussein) included: Conductive polymers are one of the important materials that possess unique properties and have multiple applications in many medical and industrial fields. In this study, two types of conductive polymers, polyindole and polymetaminophenol, were prepared using chemical methods and in the presence of ferric ternary chloride as a polymerization initiator. The prepared polymers were diagnosed using infrared spectroscopy, X-ray scattering and thermal analysis.

The second part of the study included the preparation of copolymers from both monomers in different proportions (1:1, 1:2, 2:1, 1:3, and 3:1) to study the effect of the proportions on the chemical and physical properties of the prepared polymer. The prepared copolymers were diagnosed using FTIR and XRD spectroscopy. Thermal gravimetric analysis method was used to determine the thermal stability of the prepared copolymers and the effect of the ratios on the stability. The polymers were also studied using SEM scanning electron microscopy, where the results showed that the surface topography in the form of irregular plates gives a homogeneous appearance to the copolymers, and the proportion of the constituent elements of the compound was calculated. Using X-ray Energy Dispersive EDX spectroscopy and its effect on different ratios of monomers.

As for the third part of the study, it included the preparation of polymeric composites at mixing ratios (1:1, 1:3, and 3:1) using nanomaterials, where metal oxides (CuO, ZnO, TiO2) nanoparticles were used with a size of 20 nm to prepare these composites by mixing during the chemical polymerization process. . The addition processes were carried out using different percentages of nano (5-10%) by weight of monomers.

The composite materials were diagnosed by the available methods such as X-ray scattering (XRD), where the composites showed distinct peaks indicating an increase in crystalline areas, as their re-scattering was affected by the percentage of added nanoparticles. It significantly increased the thermal stability of the prepared polymers. SEM was used to study the surface topography of the composites, where the phenotypic characteristics of the surfaces of the composites showed the presence of nanoparticles in their different shapes within the nanoscale range (20-50 nm), and the ratio of the components of the composites was calculated using X-ray energy dispersal spectroscopy (EDX).

The last axis of the study included the application of nano-grafted polymers as gas sensitizers because of the ability of these conductive polymers to be highly sensitive to different gases and what nanomaterials added to them, which also have high sensitivity characteristics. Whereas, the concentration of ammonia gas NH3 (1000ppm) with a sensitivity value of (24.12%) and a short response time (7 seconds) and recovery (3 seconds) depending on the mixing ratio (mA: 3In1) as the best value among the ungrafted copolymers.

The compounds were tested as sensitizers to ammonia gas, and the results showed that the prepared materials had the ability to be highly sensitive within very short times, even within a low concentration of ammonia gas, by calculating the sensitivity (%S) and the response and recovery time for all models after the nanoparticle grafting process. At a temperature of (C˚25), it is sensitive to NH3 gas at the same concentration (ppm1000), where the highest sensitivity value was recorded (79.14%), response time (3 seconds) and recovery time (3 seconds), when grafted with titanium oxide (TiO2) at the ratio ( 1mA:3In) for the prepared composites, which are standard values when compared with the copolymers before the grafting process.

The purpose of the message

Formation of a copolymer from two conductive polymers to study the electrical properties, thermal and morphological stability of the formed polymer and study the effect of blending ratios on these properties.

Through this study, we seek to synthesize copolymers with a number of nanometal oxides to study the effect on the electrical properties, stability, surface and crystalline topography of the prepared polymers as a result of the nanoparticles overlap within the polymeric chains.

And giving clear visions about the extent of improvement in sensing, electrical sensitivity, selectivity and detection limits towards the target materials for analysis (gases, heavy metal ions, drugs) for the prepared polymers as a result of grafting with nanoparticles, which leads to an increase in the effective surface area of the polymers and thus increases the functional performance of the analytical devices.

A study of the allergic ability of the prepared polymers to gases polluting the environment, and a comparative study between polymers grafted with nanoparticles and ungrafted polymers.

Recommended letter

Fabrication of a chemical sensitizer based on polymers and the study of its allergic and selective properties.

The study of the effect of temperature, humidity, and film thickness on conductivity and susceptibility.

Applying other gases such as CO, NO2 and H2S to the same copolymers and increasing the chance of sensing more than one gas.

And the use of different concentrations of the gases used to determine the effectiveness of the sensor from a wide range of concentrations.

The possibility of using other copolymers is available and cheap.

And the use of different nano-oxides and a practical comparison of the results to know the best sensitivity and selectivity of the nanomaterials used.

And conducting experiments using different percentages of nanoparticles (1-20%) and studying their effect on the nature of the sensor's work.

The application of electropolymerization and its comparison with chemical polymerization in terms of accuracy, conductivity and sensitivity.

And the application of the factory sensor in