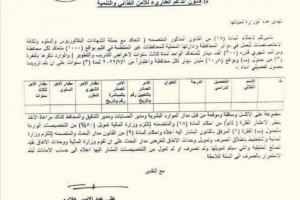

The College of Education for Pure Sciences has researched a doctoral thesis on (Preparation and Characterization of Photoluminescent Perovskite Nanoparticles Doped with Europium, Sodium, Zirconium and Magnesium). The thesis presented by the researcher (Zahraa Abbas Taama) included a study in which four types of fluorescent compounds were prepared from calcium titanate oxide CaTiO3 and calcium titanate oxide catalyzed by sodium.Na+, calcium-zirconium titanate oxide CaZrTiO3 and calcium magnesium titanate oxide CaMgTiO3, all doped with Europium ion Eu3+ with red luminescence, using a developed method by hybridizing the well-known sol-gel method with the spontaneous combustion method, which are two of the wet chemistry methods for preparing the most famous ceramics and producing nanoparticles. The resulting compounds were characterized by X-ray diffraction (XRD). The photoluminescence factors were determined, and it was found that the CRI value of the CaTiO3:Eu3+ compound is equal to The CRI value of the sodium-catalyzed CaTiO3:Eu3+ complex is 76.1, the CRI value of the CaZrTiO3:Eu3+ complex is 78.7, and the CRI value of the CaMgTiO3:Eu3+ complex is 78.9. The color temperature (CCT) was calculated and it was found that the CaTiO3:Eu3+ surface was 5534 K, while the sodium-catalyzed CaTiO3:Eu3+ surface had a CCT value of 7817 K. The color temperature of the CaZrTiO3:Eu3+ surface was 4909 K and that of the CaMgTiO3:Eu3+ surface was 5880 K. These were used in an industrial application study of the prepared red phosphor for the production of wLEDs. The compounds were also applied in the treatment of water polluted by organic dyes, as an example of aquatic environmental pollution, such as methylene blue dye and crystal violet dye. High results were obtained in treating water from pollutants, as the crystal violet dye was crushed with Ca0.98Zr0.01TiO3:0.01Eu3+ powder by 96.01% and 70.63% for the methylene blue dye. The above dyes were also broken and treated by Ca0.98Mg0.01TiO3:0.01Eu3+ surface, where methylene blue dye was broken and treated by 78.33% and crystal violet dye by 84.08%. The reaction kinetics of breaking the dyes by Ca0.98Mg0.01TiO3:0.01Eu3+ surface was studied to determine the reaction order. It was found that the reaction was of the first order for both methylene blue dye, where the value of k was 1.302 min-1, while for crystal violet dye, the value of k was equal to 1.19 min-1. Also, a study was conducted on recycling the Ca0.98Mg0.01TiO3:0.01Eu3+ surface by activating it by washing with distilled water only at laboratory temperature, where the percentage of dye removal reached more than 80%. The thesis concluded that: Doping europium-doped perovskites with alkali ions such as sodium led to an increase in the luminescence by 11 times, while for transition metals such as zirconium, the luminescence intensity increased by more than 20 times, and also for alkaline earth elements such as magnesium, compared to if the surface was not doped. This is a promising step to increase the luminescence of perovskites and its application in the field of LEDs. • The prepared perovskite has proven its ability to treat the environment from organic pollutants and reduce the effects of dyes, as the crystal violet dye was broken down by Ca0.98Zr0.01TiO3:0.01Eu3+, the breaking rate reached 96.01%, and the breaking rate of methylene blue dye reached 70.63%. As for the surface of Ca0.98Mg0.01TiO3:0.01Eu3+, it treated the crystal violet dye by 84.8% and the methylene blue dye by 78.33%, which are very high rates. The reaction kinetics were also studied and the general reaction order of the breaking down was determined, and it was a false first order through the values of k, where the value of k was found that the value of k for the crystal violet equals 1.19 min -1 and the value of k for the methylene blue dye equals 1.302 min -1. • The perovskite Ca0.98Mg0.01TiO3:0.01Eu3+ was characterized by its high efficiency in its ability to adsorb and break down many different dyes because it has the ability to reactivate its surface by washing with distilled water only. The percentage of dye recovery from the surface reached (85.9%) and (82.7%) for both methylene blue and crystal violet, respectively. Here we derive the benefit and economic return, in addition to treating the surface itself, through which the surface can be used to adsorb and break down dyes more than once, while maintaining its physical and chemical properties by more than 80%

.