The College of Education for Pure Sciences, Department of Physics, organized a scientific lecture on (Preparation and diagnosis of nanostructures based on carbon/metal oxides and their use in supercapacitor applications)

The lecture presented by the student (Mohamed Abdel Reda) included

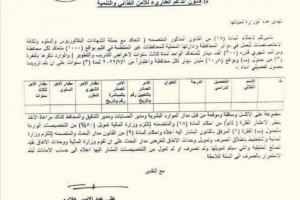

These materials were greened by easy and inexpensive chemical methods. First, prepare graphene nanosheets using liquid phase exfoliation (LPE) thin-film separation method for use in the manufacture of SC electrodes. In this model, we obtained high stability in performance and a storage capacity of Csp=5.1 F/g, in addition to an energy density of ED= 1.13 Wh/Kg and a power density of PD= 8.1 W/Kg. SEM images showed that these sheets are well arranged, with an average thickness ranging from 24.13 nm to 29.06 nm. This model has been developed by adding ZnO nanoparticles (NPs) to obtain a composite of graphene/zinc oxide nanoparticles. This compound was used to obtain an electrode in which an interaction occurs between ZnO nanoparticles (NPs) and the electrolyte, and this increases the overall performance of the model. This model showed high stability, storage capacity reached Csp = 10.53 F/g, ED energy density = 1.71 Wh/Kg, and PD power density = 12.35 W/Kg. The graphene sheet nanocomposite prepared by the LPE method and the double layer of zinc/aluminum hydroxide ZnAl-LDHs prepared by the chemical bath deposition (CBD) method, where the ZnAl-LDHs were grown on a thin aluminum piece. The purpose of this preparation is to fabricate electrodes for the SC supercapacitor and to study their electrochemical properties and surface formation of these materials. This electrode showed significant improvements in the performance of the supercapacitor model, in which the capacitance reached Csp=139.63 F/g, the energy density ED= 2.13 Wh/Kg, and the power density PD=15.35 W/Kg. Electrochemical measurements showed a longer life cycle of the model with stable overall performance after 2,000 charge and discharge cycles. Electrochemical resistance spectroscopy also confirmed these results. This study has presented a great possibility to use a mixture between graphene and zinc oxide or a zinc/aluminum oxide double layer as electrodes for the SC supercapacitor. The simple methods used in this study can also be used to manufacture other electrodes from other compounds of the same family for future energy storage systems.

The objective of this study is to prepare and characterize carbon/zinc oxide-based nanostructures and use them in the manufacture of supercapacitor (SC) electrodes.