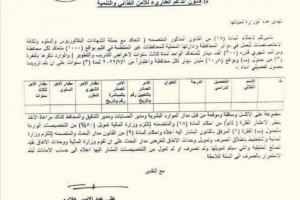

The College of Education for Pure Sciences, Department of Chemistry, has researched a master's thesis (on treating sediments in some pipes using the magnetic field and ultrasound method). The thesis submitted by the researcher (Ahmed Aref Eidan) included the current study evaluating the process of treating pipes suffering from inorganic sediments caused by industrial processes that use different water sources using laboratory devices represented by magnetism and ultrasound. This study included two axes:

The first axis:

Designing a system containing two paths. The first path is free from the effect of magnetic fields to determine the extent of the effect of magnetic fields in terms of the amount of sediments and their shapes, and the second works on the principle of magnetic fields to treat sediments. The sediment removal rate was analyzed using a scanning electron microscope (FESEM). We noticed the formation of aragonite crystals in water pipes instead of calcite crystals after magnetic treatment. The best pipes used in both systems were selected and their effect on the properties of hard water. The decrease rate of total dissolved solids (TDS) under the influence of magnetic field was 28.63% in PVC pipe, 24.65% in stainless steel pipe and 22.85% in carbon steel pipe. The values of (acid function, conductivity, turbidity) increased by (6.25%, 18.5%, 72.34%) respectively. The values of TDS and total hardness decreased by (28.63%), (8.12%) respectively with increasing applied field. The evaluation of the effect of magnetic treatment on pipes showed that PVC pipe was more efficient in treating water than stainless steel (SS) and carbon steel (CS) pipes.

Second axis:

This axis includes treating deposits by combining two techniques, the first physical technique represented by ultrasound using an ultrasonic device with a frequency of 25 kHz and the second chemical technique represented by adding weak acids (citric acid, salicylic acid and ethylenediaminetetraacetic acid). The alloys were immersed in a hard water basin until a layer of deposits was formed on the surface of the alloy and then treated using the ultrasound technique with different concentrations of the acids used with a temperature of 40 degrees Celsius.

The optimum conditions of concentration and time taken for the most suitable acid that can be used to obtain the best results with the use of ultrasound to remove deposits were determined, where citric acid was the most efficient of the acids used at a concentration of 3% and a time period of 8 minutes At a temperature of 40 Celsius. The best concentration of citric acid was applied to a sample of pipes that had previously been exposed to sediments, and it showed high efficiency and good ability to remove sediments in an ideal period of time. Combining ultrasound technology with other technologies leads to better results than using ultrasound alone to treat sediments.

Objectives

Sediments are one of the most important technical and economic problems facing water systems, which lead to damage to industrial and oil facilities. As a result, interest has emerged in trying to reduce and remove sediments caused by water in the industrial environment. Thus, the aim of the thesis was to

use technologies with economic feasibility, high efficiency and environmental friendliness represented by electromagnetic technology and ultrasound technology. And to study the effect of magnetic technology and ultrasound waves in the process of treating industrial and oil pipes that suffer from sediments.

And knowing the effect of the pipe material on the shape and quantity of deposits before and after the effect of the electromagnetic field. And an analytical study of the water specifications represented by (acid function, conductivity, turbidity, total dissolved salts and total hardness) before and after applying the electromagnetic field. And studying the shape of the deposits formed on the surface of the alloys using a scanning electron microscope (FESEM). And studying the effectiveness of the ultrasonic technology in removing deposits from alloy samples using chemical materials such as weakly dissociating acids.

And determining the optimal conditions such as concentration and time required to choose the most efficient acid and the least effect on the alloy metal.